Purchasing a filling machine for CBD and THC? Here's what to consider

Medical cannabis oil is taking over an extensive market and has become more and more widespread in recent years. At the same time, factories producing this CBD are actively seeking to purchase filling and packaging machines to supply this product, in order to keep up with its high demand and increased output.

As CBD is so valuable, and the sterile conditions are mandatory for its regulatory demands for its filling and packaging, similar to conventional medicines, there is a need for consideration and meticulousness of a number of guidelines when purchasing machinery and automation for filling and its packaging. The most seminal considerations are:

1. Experiance

A fully-automated system for filling CBD requires a great deal of know-how and experience in a wide range of fields.

It is of utmost importance to purchase a reliable and precise filling machine from a reputable manufacturer, with a long line of experience in

manufacturing combination packaging machines for a variety of functions:

- Filling systems.

- Weight control.

- Automatic provision for bottles and caps.

- Labeling, printing systems and marking.

- Inspection systems and computerized vision inspection of functions performed by the machine and alerting of rejections.

2. Accuracy

Take note not to fall for false pretenses of manufacturers that promise

filling systems having precise weight control to the hundredth- gram.

Even if the filling system is precise, and in optimal conditions can

maintain this precision, it is very difficult to create a suitable environment

to reach this level of precision, and in most cases, the machine’s speed

must be kept low and render it ineffective.

Precisions of 10ths of grams is more realistic for filling CBD,

and filling equipment for reaching this precision is more economical.

3. Quality Control

Make sure that your filling machine for CBD includes a means for

quality control:

Means such as ensuring capping; sealing the cap can save you

future cost, as well as increase the level of confidence, as your cannabis

product is not only at a high level, but is also aesthetically appealing.

4. NET. weight

Ensure that the filling machine for CBD includes a system for calculating precise weight. It is advisable for your filling machine to have the ability to

precisely calculate the weight of the product filled in each bottle of cannabis oil. Calculating the net weight of a bottle of cannabis oil is carried out

by an intelligent program that weighs the bottle before and after filling, and even makes sure to remove bottles that deviate from the desired weight.

In this way, you can ensure that your CBD product is in line with the weight guaranteed and is not defective.

5. Easy To Clean

The filling machine is easy to clean. Easy daily cleaning is especially

important for CBD filling machines. Cleaning can take up a great deal

of precious time – time that would be better utilized by filling up

bottles of CBD.

Therefore, it is of utmost importance to purchase a filling machine

that is easily maintained, and requires the minimum amount

of time for cleaning.

6. Easy Transition

Easy transition between products: It is advisable to choose a machine

that transitions easily from one product to another. CBD products often

come in different sizes and quantities. It is important to choose a

filling machine that enables a quick transition of formats,

thus saving precious time.

7. Opertion

A filling machine that is easy to operate: It is advisable to choose a CBD filling machine with a user-friendly intuitive interface. A filling machine that is

easy to operate can greatly ease operation thus making it possible to utilize the time for filling bottles, instead of looking for parameters on the screen.

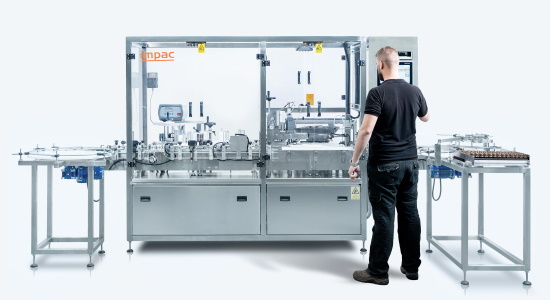

Impac Engineering Ltd. – over 45 years of manufacturing filling and packaging machines and complete lines, specializing in filling and packaging cannabis products, such as CBD, THC and cannabis flowers, having manufactured scores of machines and production lines in diverse fields.

We are at your service to assist you in choosing the most suitable machinery for your use, and to provide you with the most trustworthy and precise solution for your needs.