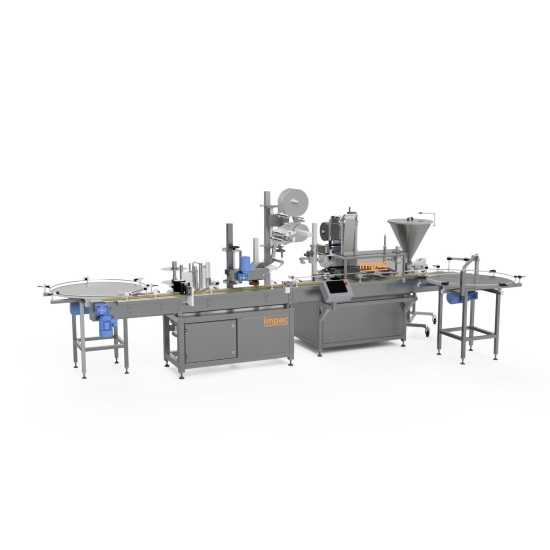

PYTHON- Automatic Filling and Capping Machine

Categories: Jars Filling machines , cannabis capsules filling and packaging

The Python series serves as the ultimate solution for filling, sealing and automatic labeling on bottles and jars.

The meticulous and uncompromising design and the machine's maximum suitability for each and every product allows for utmost flexibility and adaptation for working with a wide range of products and packaging in multiple shapes and sizes.

This machine is suitable for filling a wide variety of products, ranging from liquids to creams; the machine is built with the ability to handle products with varying levels of viscosity.

And what's more, a filling system suited for powders, granular products and capsules can be integrated to the machine.

It is possible to combine a number of formats for filling various-sized bottles and jars, with quick and easy conversion between products.

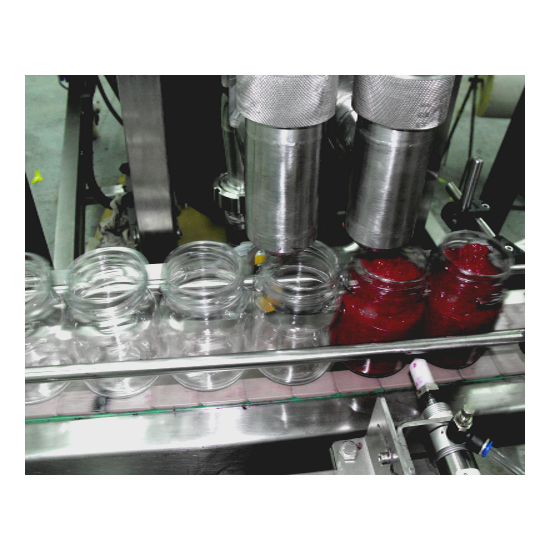

Filling

> High accuracy.

> Anti-dripping system.

> Easy to take apart and reassemble for daily clean-up.

> Suitable for a wide variety of products – including solids, such as powders,

capsules, granular products, and liquids and creams, both homogenous

and non-homogenous.

Capping

> Torque controlled capping.

> Cap presence verification.

Labelling

> Precise self-adhesive labeling.

> Option for real-time labeling.

> A wide range of labeling applications.

> A flawlessly turned-out product.

Materials

> All product contact parts are stainless steel and FDA-approved polymers

for food grade materials.

> Stainless steel structure.

> Not-in-contact parts made from anodized aluminum and plastic,

all conform FDA standards.

> The machine is capable of sustaining frequent washing,

corrosive environment and rigorous handling.

Operation & Control

> PLC & HMI control with user-friendly interface.

> Quick-adjustment parameters to accommodate a diverse range of products.

> Optional- remote assistance.

> Possible interfacing to the factory database in order to receive data analysis straight from the machine.

| Maximum Output | 70 units/min |

| Lanes | 1-6 |

| Max filling volume | Up to 1.5 liters |

| Product type | Pastes, liquids, powders, capsules and granulated products. |

| Air Pressure | 6 atm |

* Indicated data may change in accordance with the type of product, volume of the filling and required machine configuration.

- Front line: feeding systems, de-palletizers, unscrambling systems.

- Core production.

- Labelling- top, bottom labelling, wraparound labelling, multiple side labelling and more.

- Verification systems- label presence, cap presence, product level control, etc.

- End of line: case packing, palletizers, wrapping systems, etc.