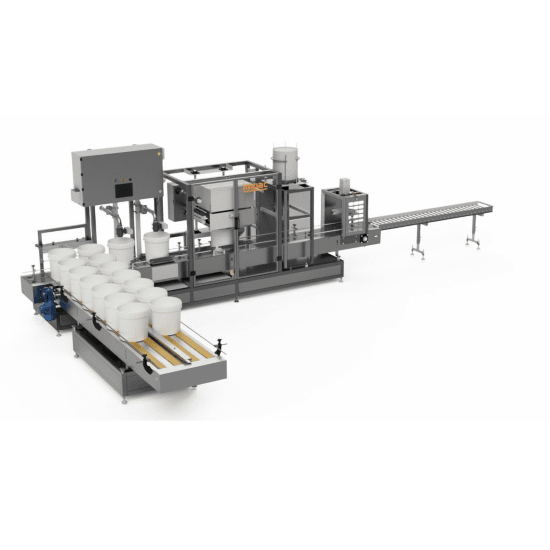

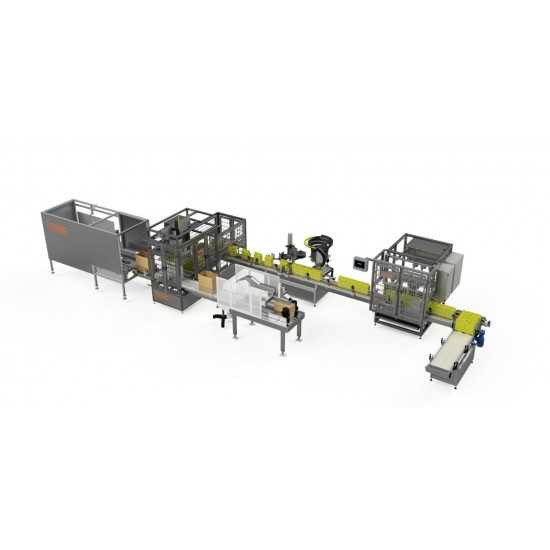

MAMBA - Automatic Filling, Capping and Sealing Machine

Categories: Cups filling machines , Pails Filling machines

The MAMBA has over four decades of experience, and is a forerunning machine for filling pails and jerrycans.

This filling machine provides the optimal and most flexible solution for filling cups, pails and jerrycans.

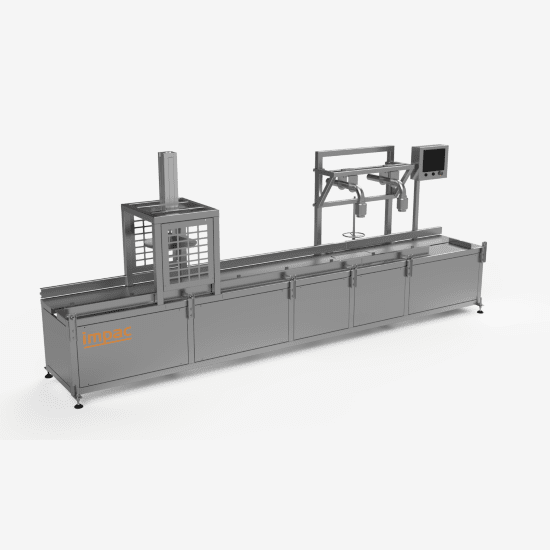

The machine is tailor-made and calibrated for each customer's product specifications. Its linear construction enables integrating a wide range of filling and packaging applications, and maximum accommodation to the product.

The machine is suitable for multiple packaging types, with easy format conversion. Filling systems suitable for liquids, creams, powders and granular products can be integrated in the machine.

Servomotor enables a controlled and precise transition between the various work stations, thus enhancing the machine's efficiency.

Filling

> High accuracy.

> Anti-dripping system.

> Easy to take apart and reassemble for daily clean-up.

> Suitable for a wide variety of products – including solids,

such as powders, granular products, and liquids and creams,

both homogenous and non-homogenous.

> Multiple filling systems can be applied for various types of products.

Capping

> Torque controlled capping.

> Cap presence verification.

Sealing

> Optional- sealing from laminated film roll.

> Option for cutting and inserting sheets of foil into the pails.

> Optional- nitrogen purge.

Materials

> All product contact parts are stainless steel and FDA-approved polymers

for food grade materials.

> Stainless steel structure.

> Not-in-contact parts made from anodized aluminum and plastic,

all conform FDA standards.

> The machine is capable of sustaining frequent washing,

corrosive environment and rigorous handling.

Operation & Control

> PLC & HMI control with user-friendly interface.

> Quick-adjustment parameters to accommodate a diverse range of products

> Optional- remote assistance.

> Possible interfacing to the factory database in order to receive data analysis straight from the machine

| Model | MAMBA 5 | MAMBA 30 |

| Maximum output | 30 units/min | 10 units/min |

| Lanes | 1-2 | 1-2 |

| Max package dimension | Upon customer's request | |

| Max filling volume | 5 liter | 30 liter |

| Product type | Pastes, liquids, powders and granulated products | |

| Air pressure | 6 atm | |

*Indicated data may change in accordance with the type of product, volume of the filling and required machine configuration

- Front line: feeding systems, de-palletizers, unscrambling systems.

- Core production.

- Labelling- top, bottom labelling, wraparound labelling, multiple side labelling and more.

- Verification systems- label presence, cap presence, net. weight calculation, product level control, etc.

- End of line: case packing, palletizers, wrapping systems, etc.